Conquering the Bilge: Mastering the Art of Bilge Pump and Float Switch Wiring

A sinking feeling. It’s the last thing any boat owner wants to experience. But water intrusion is a constant threat, making a properly functioning bilge pump system absolutely crucial. Understanding how to wire a bilge pump and float switch isn’t just a handy skill – it's a fundamental aspect of responsible boat ownership.

This comprehensive guide dives deep into the world of bilge pump wiring. We'll explore everything from basic electrical principles to troubleshooting common issues, ensuring you have the knowledge to keep your vessel dry and seaworthy. Whether you're a seasoned sailor or a novice boat owner, mastering the art of bilge pump and float switch wiring is an investment in peace of mind.

Historically, manual bilge pumps were the norm, requiring constant attention and physical effort. The advent of automatic bilge pumps, coupled with float switches, revolutionized boat safety. These automated systems provide continuous monitoring and water removal, significantly reducing the risk of sinking due to unnoticed leaks or heavy rainfall. Proper bilge pump wiring is paramount for these automatic systems to function reliably.

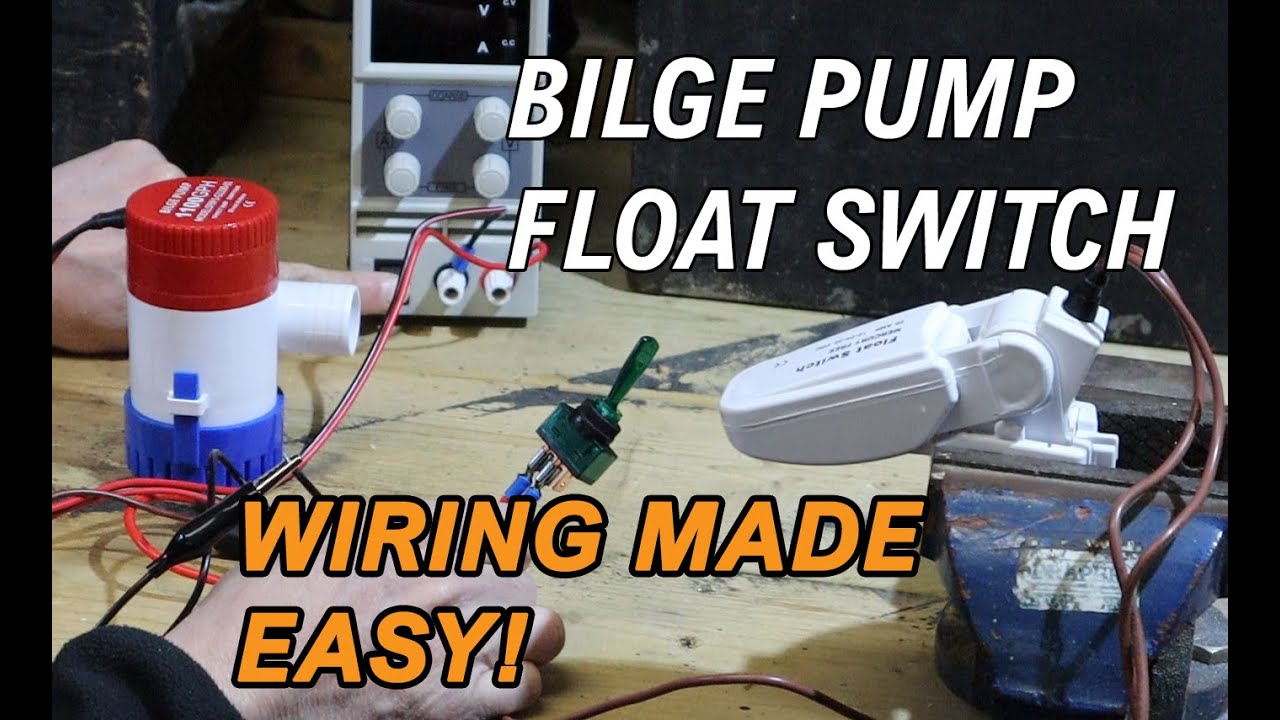

The core of any automatic bilge system lies in the interconnected workings of the pump and the float switch. The float switch, a buoyant device, detects rising water levels. When the water reaches a certain point, the float switch activates, completing the circuit and triggering the bilge pump to begin removing water. Incorrect wiring can lead to malfunctions, ranging from a constantly running pump to a completely inactive system, rendering your boat vulnerable.

A float switch is essentially a mechanical switch triggered by the buoyancy of its float. As water rises, the float rises with it, eventually reaching a point where it activates the switch. This switch then closes the electrical circuit to the bilge pump, powering it on. When the water level drops, the float drops, opening the circuit and turning the pump off. Understanding this simple mechanism is key to wiring the system correctly.

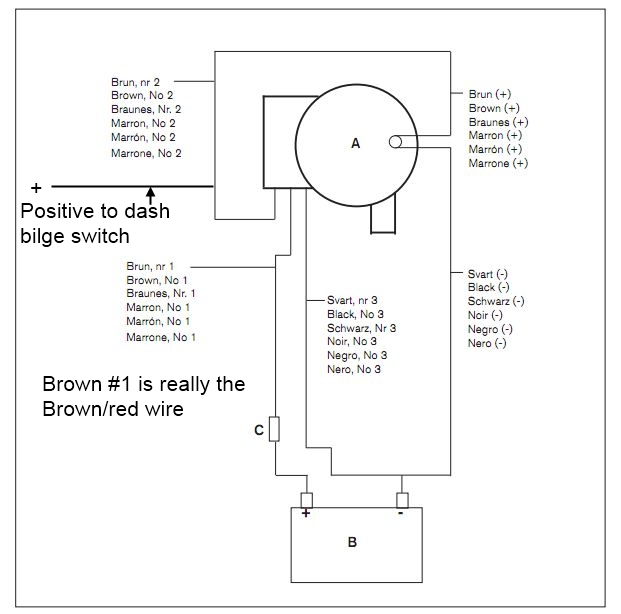

Connecting a bilge pump and float switch involves wiring the float switch in series with the pump's positive wire. This ensures that the pump only receives power when the float switch is activated. A fuse should always be included in the circuit to protect the wiring and prevent overloads. The negative wire of the pump is typically connected directly to the boat's ground.

Three key benefits stand out when discussing proper bilge pump wiring: increased safety, reduced boat damage, and peace of mind. A correctly wired system automatically removes unwanted water, preventing potential sinking. This automated operation also minimizes the risk of water damage to the boat's interior and electrical systems. Finally, knowing your bilge system is reliable provides invaluable peace of mind, allowing you to enjoy your time on the water without constantly worrying about potential leaks.

Action Plan for Wiring a Bilge Pump:

1. Disconnect the boat's battery. 2. Locate a suitable position for the float switch. 3. Connect the float switch wires to the pump's positive wire. 4. Connect the pump's negative wire to ground. 5. Install an inline fuse. 6. Reconnect the battery and test the system.

Advantages and Disadvantages of Different Wiring Approaches

Direct wiring provides a simple setup, but offers less control. Using a switch panel adds control and allows for manual operation, but adds complexity.

Best Practices:

1. Use marine-grade wiring. 2. Properly fuse the circuit. 3. Ensure all connections are waterproof. 4. Regularly test the system. 5. Inspect the float switch for debris.

FAQs

Q: What gauge wire should I use? A: Consult your pump's specifications.

Q: How often should I test my bilge pump? A: At least once a month.

Q: What if my pump isn't working? A: Check the fuse, wiring, and float switch.

Q: Can I wire multiple pumps to one float switch? A: Yes, but consider the amp draw and wire gauge.

Q: Where should I place the float switch? A: In the lowest part of the bilge, where water collects first.

Q: What type of fuse should I use? A: A marine-grade fuse with the correct amperage rating.

Q: Can I use automotive wiring? A: No, use marine-grade wiring for corrosion resistance.

Q: How do I test the float switch? A: Manually lift the float and listen for the pump to activate.

Tips and Tricks

Use wire ferrules for secure connections. Apply dielectric grease to all connections to prevent corrosion. Label all wires clearly for future troubleshooting.

In conclusion, understanding how to wire a bilge pump and float switch is an essential skill for any boat owner. A properly functioning bilge system is crucial for preventing potentially catastrophic sinking and minimizing water damage. By following the steps outlined in this guide, using best practices, and regularly testing your system, you can ensure the safety and longevity of your vessel. This knowledge not only protects your investment but also gives you the confidence to enjoy your time on the water, knowing you're prepared for whatever comes your way. Don't wait until it's too late. Take the time to understand and maintain your bilge system, and experience the peace of mind that comes with knowing your boat is equipped to handle the unexpected. Take action today and ensure your next voyage is a safe and enjoyable one.

Sterling bank loan options your complete guide

When is the new season of ink master everything you need to know

Unlocking engine performance your guide to pennzoil sae 30 motor oil sds