Understanding Aircraft Engine-Driven Fuel Pumps

The heart of any aircraft lies in its ability to generate power and sustain flight. A critical component ensuring this capability is the fuel system, and at its core often resides the engine-driven fuel pump. These pumps are the workhorses responsible for delivering fuel from the tanks to the engine, maintaining the precise pressure required for optimal combustion and performance. But how much do we really know about these essential devices? This article dives deep into the world of aircraft engine-driven fuel pumps, exploring their significance, functionality, and the critical role they play in keeping aircraft airborne.

Imagine a scenario where fuel flow is disrupted mid-flight. The consequences can be catastrophic. This is why understanding the intricacies of the fuel pump system, particularly the engine-driven pump, is paramount for pilots, mechanics, and anyone involved in aviation. This type of fuel pump is mechanically linked to the engine, typically through a driveshaft or gear train, ensuring fuel delivery is directly proportional to engine speed. This inherent connection makes them reliable and highly effective, especially in demanding flight conditions.

The history of aircraft engine-driven fuel pumps is intertwined with the evolution of aircraft engines themselves. As engines became more powerful and complex, the need for a robust and dependable fuel delivery system became crucial. Early aircraft relied on gravity-fed systems, but these proved inadequate for high-performance aircraft. The advent of engine-driven pumps marked a significant advancement, allowing for greater fuel flow and consistent pressure regardless of the aircraft's attitude or maneuvers. This innovation played a vital role in enabling longer flights, higher altitudes, and increased maneuverability.

One of the primary advantages of an engine-driven fuel pump is its simplicity and reliability. Because it’s mechanically linked to the engine, there's no need for complex electrical systems or separate power sources. This reduces the potential points of failure and simplifies maintenance. These pumps are generally rugged and designed to withstand the harsh operating environment of an aircraft engine, making them a durable choice for demanding applications.

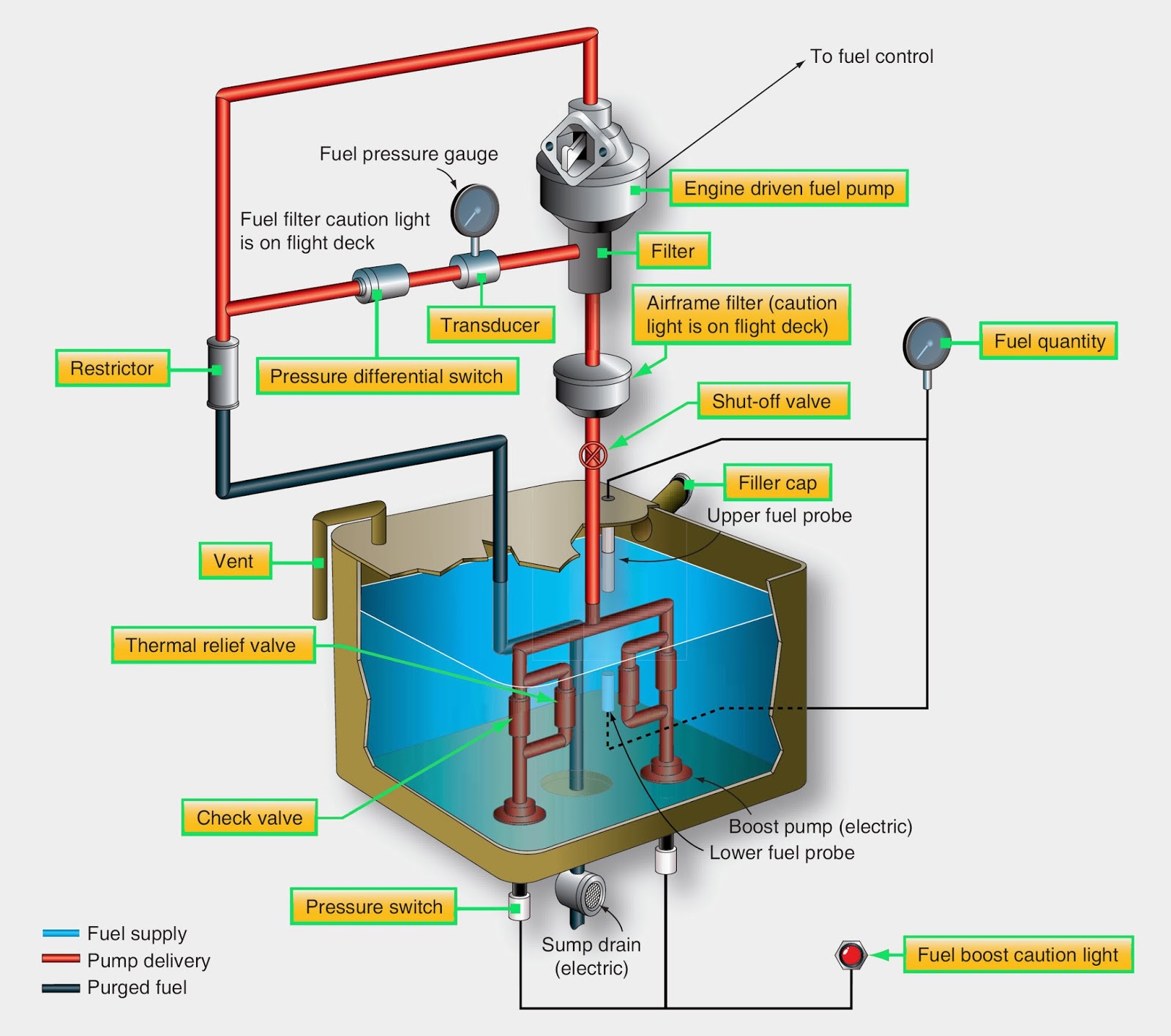

However, engine-driven pumps are not without their limitations. A significant issue is their vulnerability to vapor lock, a phenomenon where fuel vaporizes due to low pressure or high temperatures, disrupting fuel flow. This can occur in hot weather or at high altitudes and can lead to engine power loss. To mitigate this risk, many aircraft employ fuel system designs that incorporate features like boost pumps or vapor separators to ensure consistent fuel delivery.

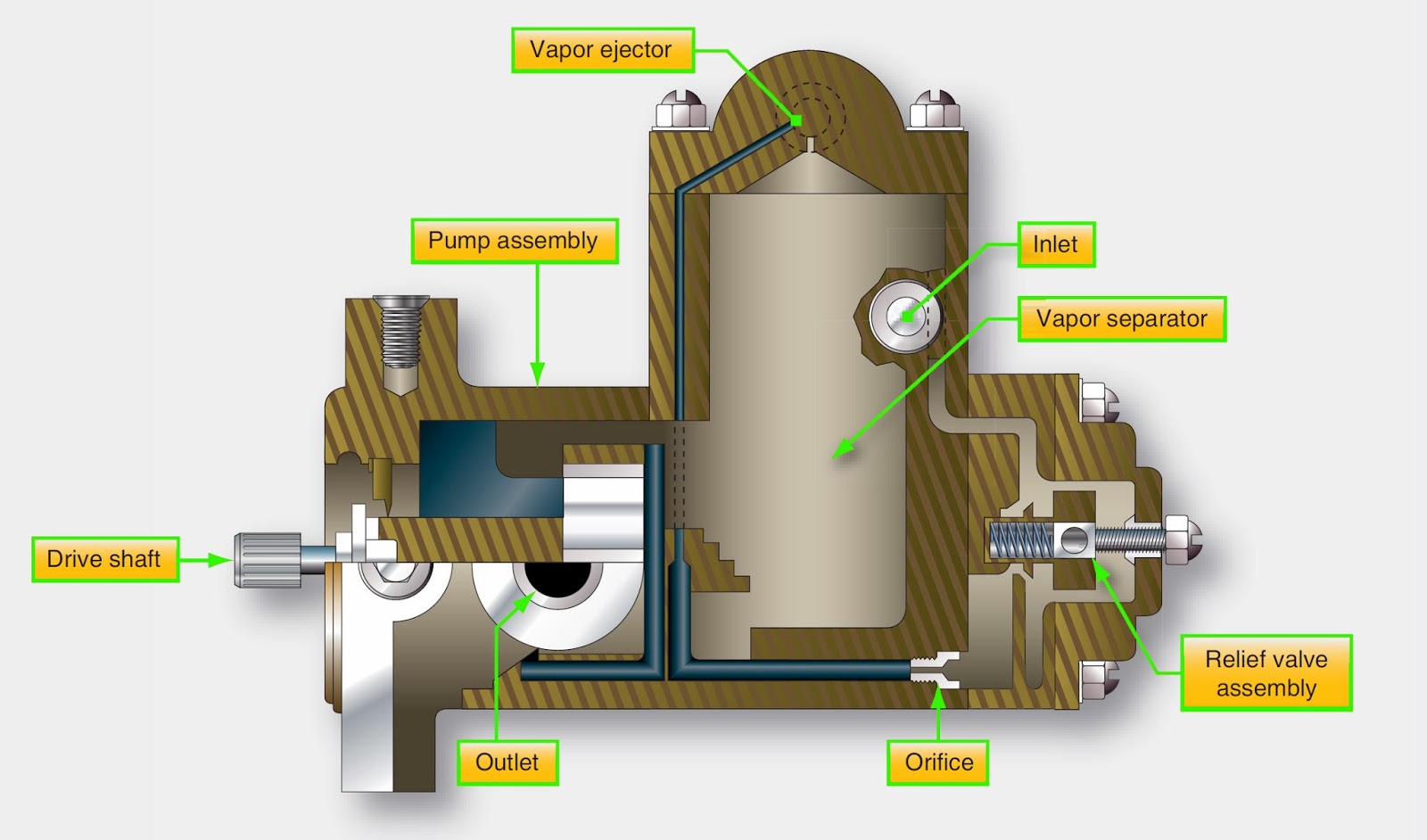

The engine-driven fuel pump functions as the primary fuel delivery system in many aircraft. It draws fuel from the tanks and delivers it under pressure to the engine’s fuel control unit. This unit then meters the fuel flow based on the engine's power requirements. A typical engine-driven pump consists of a rotating impeller within a housing. As the engine turns, it drives the impeller, which creates pressure and pushes fuel through the system.

Advantages and Disadvantages of Engine-Driven Fuel Pumps

| Advantages | Disadvantages |

|---|---|

| Reliability and simplicity | Susceptibility to vapor lock |

| Directly proportional fuel delivery to engine speed | Limited control over fuel pressure independent of engine speed |

| No separate power source required | Can be less efficient at low engine speeds |

One best practice for maintaining engine-driven fuel pumps is regular inspection for leaks and wear. Another important practice is adhering to the manufacturer’s recommended maintenance schedule, which typically includes periodic overhauls or replacements. Pilots should also be aware of the symptoms of fuel pump issues, such as engine roughness or power loss, and take appropriate action if they arise.

A common challenge related to engine-driven fuel pumps is vapor lock. Solutions include installing boost pumps to maintain fuel pressure or using fuel additives to reduce vaporization. Another challenge can be mechanical wear and tear. The solution is regular inspections and timely replacement of worn components.

In conclusion, the engine-driven fuel pump is a critical component of many aircraft fuel systems. Its reliability, simplicity, and direct connection to the engine make it a robust solution for ensuring consistent fuel delivery. While challenges like vapor lock exist, proper maintenance, design considerations, and pilot awareness can mitigate these risks. Understanding the workings, benefits, and potential issues related to these pumps is essential for anyone involved in the world of aviation. As aircraft technology continues to evolve, the engine-driven fuel pump remains a steadfast and vital part of ensuring safe and efficient flight, powering our journeys through the skies for generations to come. Continuing education on the latest advancements and best practices related to aircraft fuel systems is crucial for ensuring continued airworthiness and operational safety.

Crafting the perfect end of year message for teachers

Black cherry gas strain

Bsf john lesson 15 day 3