Wrangler Wheel Wisdom: Mastering Jeep TJ Lug Nut Torque

Ever felt that subtle wobble in your steering wheel while conquering a rocky trail? Or perhaps heard a disconcerting clicking sound emanating from your Jeep TJ’s wheels? These seemingly minor issues can point to a critical, often overlooked aspect of Jeep ownership: proper lug nut torque. Ignoring this seemingly mundane detail can lead to anything from a loose wheel to a catastrophic failure, jeopardizing your safety and your off-roading experience.

Understanding the correct Jeep TJ lug nut torque specifications isn’t just about memorizing a number; it's about understanding the physics at play. Properly torqued lug nuts ensure even pressure distribution across the wheel’s mounting surface, creating a secure and stable connection between your Jeep and the terrain. This translates to better handling, improved braking performance, and most importantly, a safer ride.

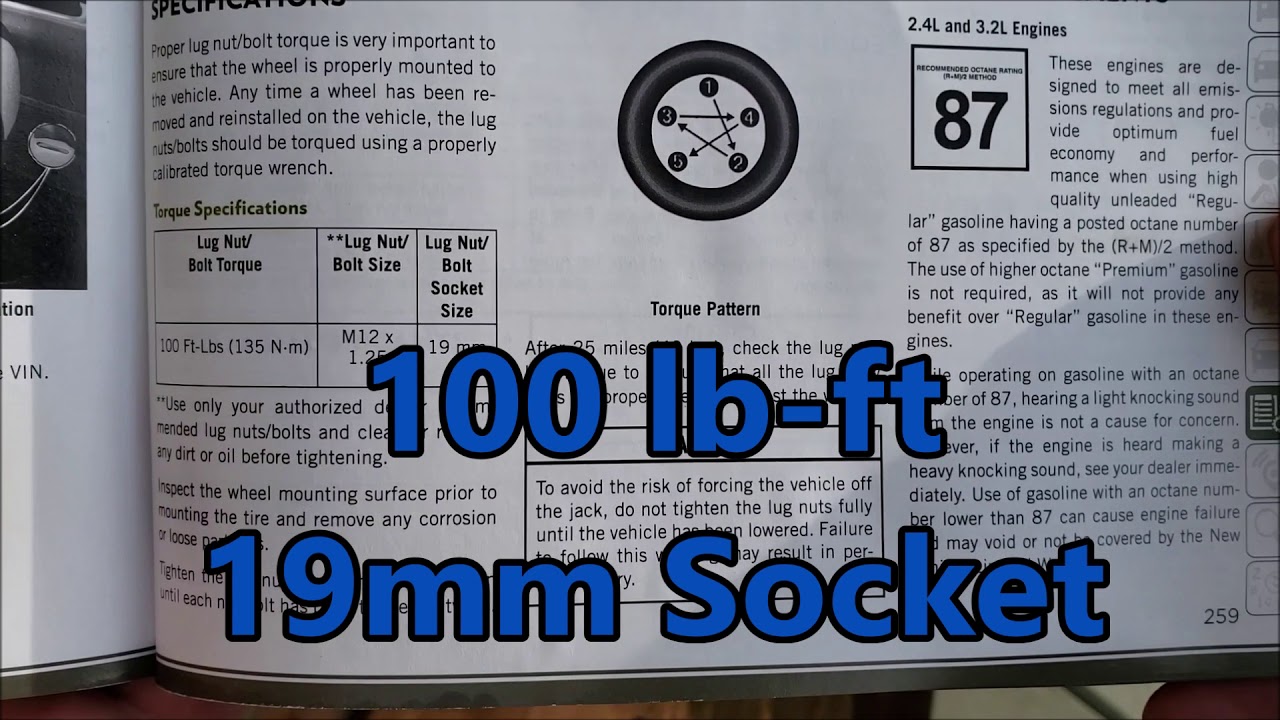

While the specific torque value for a Jeep TJ is readily available (typically around 85-100 ft-lbs), it's crucial to consult your owner's manual for the precise recommendation for your specific year and model. Variations exist, and using the wrong torque specification can be just as damaging as under-torquing or over-torquing. This seemingly small detail is an integral part of maintaining your Jeep's integrity, impacting everything from wheel bearing life to overall suspension health.

Historically, lug nuts have evolved from simple square nuts to the more sophisticated designs found on modern vehicles. With the rise of off-road vehicles like the Jeep TJ, the importance of proper lug nut tightening became even more critical. The demanding conditions of off-roading, with its constant vibrations and jarring impacts, place immense stress on the wheel assemblies. This emphasizes the need for meticulous attention to lug nut torque to ensure wheel integrity in challenging environments.

One common misconception surrounding Jeep TJ lug nut torque is the "tighter is better" mentality. Over-torquing can strip the threads, warp the wheel studs, and even damage the brake rotors. Under-torquing, on the other hand, allows the lug nuts to loosen, potentially leading to a lost wheel and a dangerous situation. Finding the correct balance, the "Goldilocks" torque, is crucial. This is where a properly calibrated torque wrench becomes an indispensable tool for every Jeep TJ owner.

One of the benefits of correct lug nut tightening is enhanced safety. Properly torqued lug nuts minimize the risk of wheel detachment, ensuring a secure connection to the vehicle.

Another benefit is improved handling and performance. Properly tightened lug nuts contribute to even pressure distribution, enhancing stability and control.

Proper torque also extends the life of wheel components. Even pressure prevents premature wear and tear on wheel studs, bearings, and rotors.

Step-by-step guide to tightening your Jeep TJ lug nuts:

1. Consult your owner's manual for the correct torque specification.

2. Use a calibrated torque wrench.

3. Tighten the lug nuts in a star pattern.

4. Recheck the torque after driving a short distance.Advantages and Disadvantages of Proper Lug Nut Torque

| Advantages | Disadvantages |

|---|---|

| Increased safety | Requires a torque wrench |

| Improved handling | Takes more time than simply tightening |

Best Practices:

1. Use a calibrated torque wrench.

2. Tighten in a star pattern.

3. Recheck torque after driving.

4. Inspect lug nuts regularly.

5. Consult your owner's manual.FAQs:

1. What is the correct torque spec for my Jeep TJ? (Consult your owner's manual)

2. What type of torque wrench should I use? (Click-type or beam-type)

3. How often should I check my lug nut torque? (After tire rotations, off-roading trips, or if you notice any unusual noises)

4. Can I use an impact wrench to tighten lug nuts? (Not recommended)

5. What happens if I over-torque my lug nuts? (Stripped threads, warped studs, damaged rotors)

6. What happens if I under-torque my lug nuts? (Loose wheels, potential wheel detachment)

7. How do I know if my torque wrench is calibrated? (Take it to a professional for calibration)

8. What are the signs of a loose lug nut? (Wobbling, clicking noises, vibrations)Tips and Tricks:

Keep a torque wrench in your Jeep for trailside adjustments.

Check your lug nut torque after any significant off-road excursion.In conclusion, mastering the art of Jeep TJ lug nut torque is about more than just tightening some bolts; it's about understanding the fundamental principles that contribute to a safe, reliable, and enjoyable off-road experience. From the historical context of lug nut evolution to the practical application of proper tightening techniques, every aspect plays a vital role in ensuring optimal performance and safety. By prioritizing regular checks, using a calibrated torque wrench, and adhering to the manufacturer's recommendations, you not only protect your investment but also enhance your overall off-roading adventures. Don't underestimate the power of this small detail – it can make all the difference between a smooth ride and a roadside disaster. Take the time to learn the correct procedures, invest in the right tools, and empower yourself with the knowledge that comes with understanding the critical role of Jeep TJ lug nut torque. Your Jeep, and your safety, will thank you for it.

Discovering mount zion methodist church a cornerstone of atlanta ga

Colores para pintar una casa por fuera the ultimate guide

Groovy rebirth unearthing the magic of popular 70s fashion trends